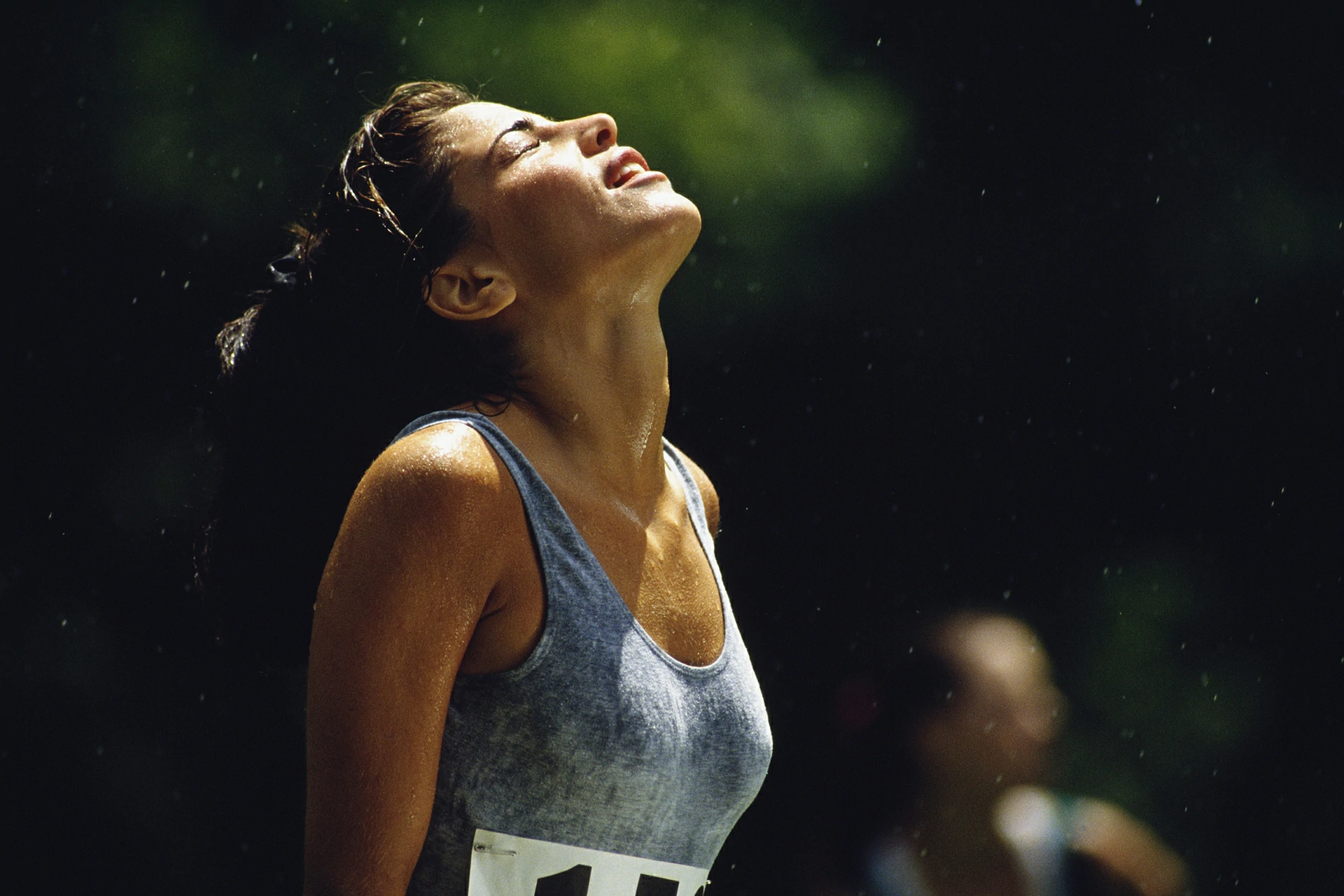

Moisture wicking is the process of pulling sweat away from your skin during a workout. Fabrics designed for moisture wicking draw sweat to the surface of your clothing where it can evaporate, keeping you comfortable and dry throughout your exercise session. This capability arises from capillary action, where moisture moves through tiny pores in the fabric to its outer surface. Once there, surface tension causes the moisture molecules to evaporate swiftly. This guide covers everything you need to know about moisture-wicking fabric, including their composition, functionality, and the most suitable fabric types for various workouts.

There are three primary methods to impart wicking properties to a garment:

-Yarn Construction:

Wicking yarn differs from regular yarn by having a non-round shape, such as cross or flower-shaped, with more spaces and channels. This design facilitates capillary action, where tiny tubes (capillaries) within the yarn enable moisture to move through the fabric. Typically made from synthetic filaments like polyester and nylon, wicking yarn allows sweat to be wicked away from the body, aiding evaporation into the air.

-Knitting Structure:

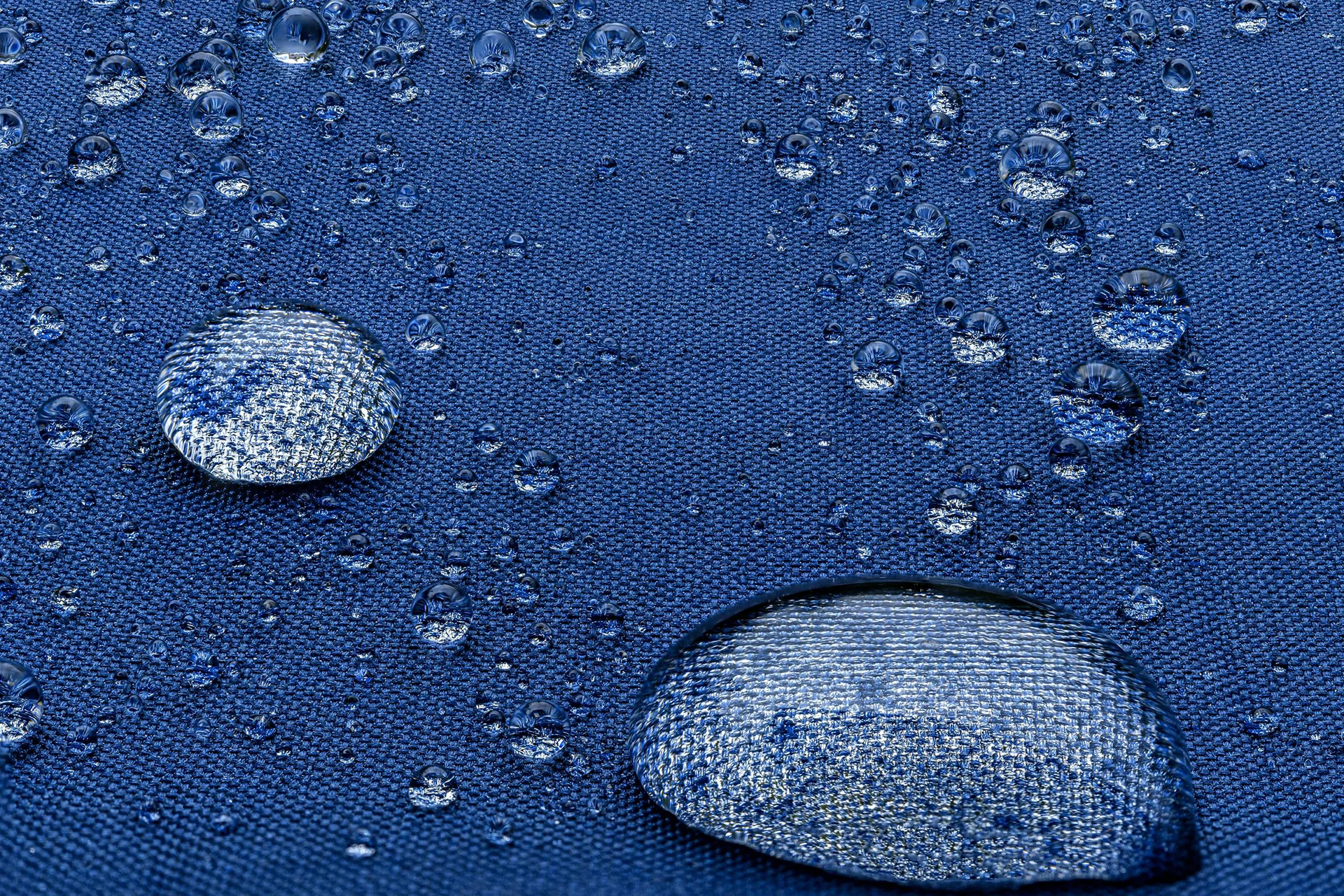

Known as one-way or mechanical wicking, this method involves knitting fabric in specific patterns. These patterns direct moisture towards the outer layer of the garment, where it spreads over a larger surface area. This process accelerates evaporation, enhancing moisture management.

-Chemical Finish:

To impart wicking properties to regular fabrics, a chemical finish containing hydrophilic molecules can be applied during dyeing or finishing processes. These additives bond with the fabric’s surface, making it hydrophilic. While chemical finishes are cost-effective compared to wicking yarn, they gradually diminish with washing.

Sweat is crucial for regulating body temperature, but when absorbed by workout clothes, it can lead to discomfort—alternating between feeling hot and cold. Moisture-wicking fabric help maintain comfort by reducing bacterial growth and preventing chafing.

Synthetic Moisture-Wicking Fibers: Synthetic fibers are chemically engineered to enhance moisture-wicking properties. Common types include:

– Polyester: Lightweight, durable, quick-drying, and wrinkle-resistant.

– Polypropylene: Water-repellent, breathable, and retains heat effectively.

– Nylon: Stretchy, mildew-resistant, lightweight, and quick to dry.

– Acrylic: Lightweight, shape-retaining, and good at retaining heat.

– Spandex: Highly elastic, smooth, and moderately moisture-wicking.

– GORE-TEX®: Waterproof, windproof, ideal for layering and enduring various weather conditions.

Natural Moisture-Wicking Fibers: Natural fibers possess inherent moisture-wicking capabilities, rooted in their natural functions for plant growth and animal cooling. Derived from organic materials, they offer an environmentally-conscious alternative to synthetics.

– Bamboo: Breathable, odour-resistant, and stretchy, bamboo’s natural moisture-wicking ability comes from its water-absorbing properties, thriving in hot, humid environments.

– Wool: Naturally breathable and thermoregulating, wool absorbs moisture into its fibers while effectively releasing it from both the surface and spaces between fibers, maintaining insulation.

– Rayon: Derived from wood pulp, rayon combines natural and synthetic elements. It is known for being wrinkle-resistant, lightweight, and quick-drying.

Layne | 09-03-2024 | Views 394 times

Sweatshirt Knit Fabric Series: Functions and Composition 1. Introduction to Sweatshirt Fabric Sweatshirt fabric is one of the most basic fabrics used in circular knitting. As the name suggests, it is used for making sweatshirts. In technical terms, it is know...

Layne | 09-02-2024 | Views 366 times

Are you looking for common swimwear fabrics? 1. Common Swimwear Fabrics In the blazing summer, it’s the season for swimwear to shine. So, what are the most commonly used fabrics for swimwear, and how should you select and care for them? 1.1 Lycra (DuPont L...

Layne | 09-01-2024 | Views 394 times

The Versatility of Polyester Stretch Fabric 1. Introduction Polyester stretch fabric is a standout in the textile industry, known for its flexibility, durability, and comfort. This fabric, made from a blend of polyester and elastane (or spandex), is widely us...

Layne | 08-31-2024 | Views 400 times

Nylon Stretch Fabric: The Perfect Blend of Strength and Flexibility 1. What is Nylon Stretch Fabric? Nylon stretch fabric is created by blending nylon fibers with elastane or spandex. Nylon itself is a synthetic fiber known for its toughness, resistance to we...

Layne | 08-22-2024 | Views 433 times

RPET Non-Woven Fabric: A Perfect Blend of Eco-Friendliness and Practicality 1. Background As environmental awareness increases, RPET non-woven fabric is becoming a popular choice in the market. RPET (Recycled Polyethylene Terephthalate) non-woven fabric not o...

Layne | 08-21-2024 | Views 506 times

Introduction to 10 Fabric Finishing Processes 1. Purpose of Fabric Finishing Finishing is a technical treatment that imparts color effects, shape effects (such as smoothness, velvety texture, stiffness, etc.), and practical effects (such as water resistance, ...

Contact us now for a free consult!