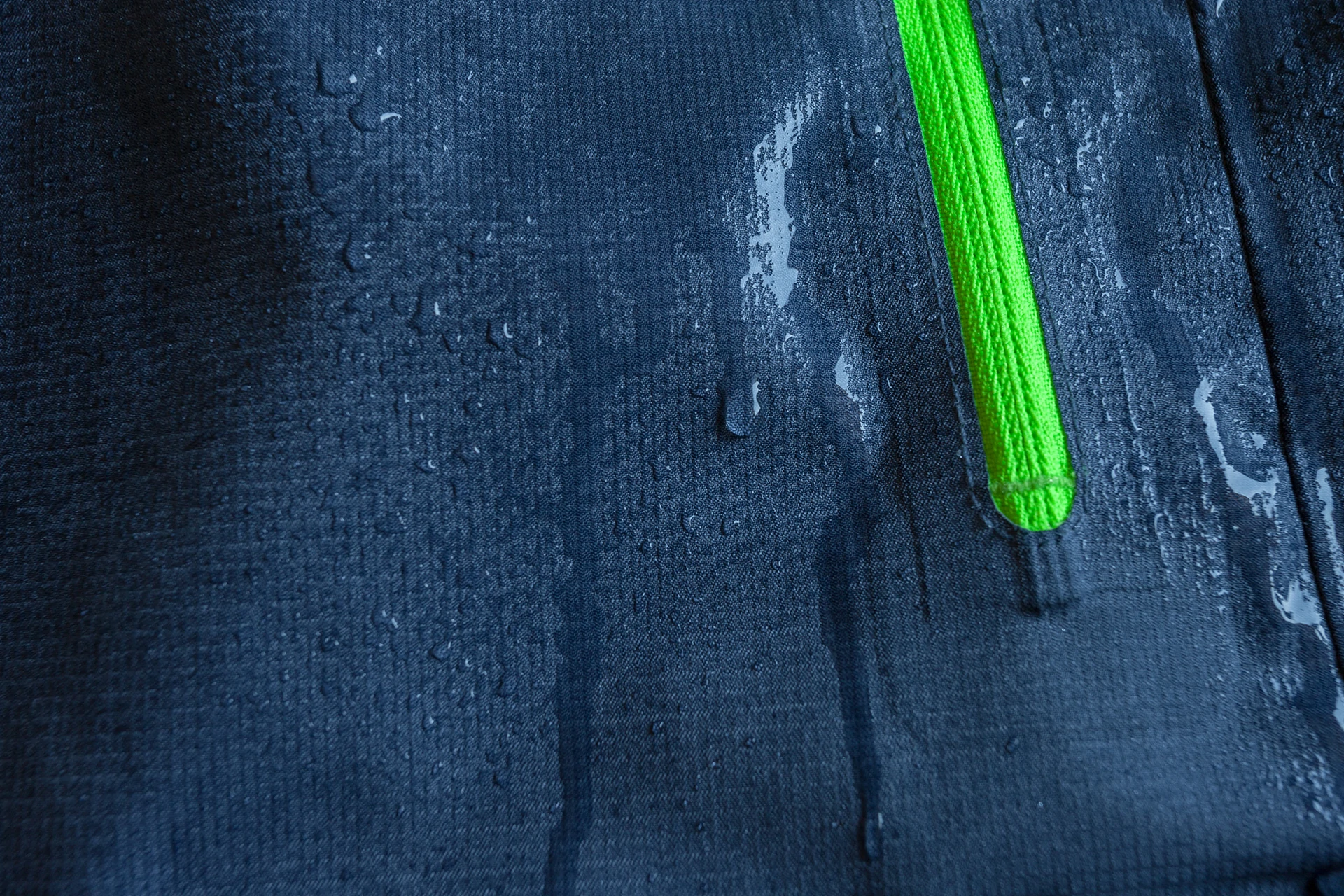

Waterproof and breathable (WPB) fabrics are specialized materials designed to repel water from the outside while allowing moisture vapor to escape from the inside. This dual functionality is essential for maintaining comfort and dryness, particularly in outdoor environments.

1. Outer Layer (Face Fabric):

– Typically made from nylon or polyester.

– Treated with Durable Water Repellent (DWR) to make water bead up and roll off.

2. Membrane or Coating:

– Positioned beneath the outer layer.

– Composed of materials like ePTFE (expanded polytetrafluoroethylene) or PU (polyurethane).

– The membrane has microscopic pores large enough for water vapor to escape but small enough to block liquid water.

3. Inner Layer (Lining):

– Protects the membrane and enhances comfort.

– Often made from tricot or mesh, which adds breathability and moisture-wicking properties.

The WPB fabric functions through a combination of hydrophobic and microporous properties. The outer DWR treatment repels water, while the membrane’s micro-pores allow perspiration in the form of water vapor to pass through. This technology ensures that while external water is kept out, internal moisture is efficiently managed, preventing the wearer from feeling clammy or wet from sweat.

1. Protection from the Elements:

– Waterproofing: Keeps rain, snow, and moisture out, ensuring the wearer stays dry in wet conditions.

– Windproofing: Many WPB fabrics also provide wind resistance, adding an extra layer of protection against cold and blustery weather.

2. Comfort and Breathability:

– Moisture Management: By allowing sweat to escape, WPB fabrics prevent overheating and excessive sweating, maintaining a comfortable microclimate inside the jacket.

– Temperature Regulation: Breathable fabrics help in regulating body temperature by allowing excess heat to dissipate.

3. Versatility and Durability:

– Multi-Season Use: Suitable for a variety of weather conditions, making them ideal for activities such as hiking, skiing, mountaineering, and other outdoor sports.

– Durable: Designed to withstand rugged outdoor use, these fabrics are often abrasion-resistant and long-lasting.

4. Enhanced Performance:

– Lightweight: Modern WPB fabrics are designed to be lightweight, ensuring that the jacket does not become a burden during extended wear.

– Flexibility: Provides ease of movement, crucial for active pursuits where mobility is essential.

Several brands have developed their own WPB technologies, each with unique features:

– Gore-Tex: Known for its robust waterproofing and breathability, Gore-Tex is one of the most recognized WPB fabrics.

– eVent: Offers excellent breathability with Direct Venting technology, which allows air to flow directly through the fabric.

– Polartec NeoShell: Combines breathability and waterproofing with a soft, flexible feel.

– H2No by Patagonia: Provides a durable and highly waterproof option with an emphasis on environmental sustainability.

Waterproof and breathable fabrics represent a significant advancement in outdoor apparel technology, combining the essential elements of protection, comfort, and performance. For anyone looking to explore the great outdoors, whether through hiking, skiing, or simply navigating a rainy city, an outdoor jacket made from WPB fabric is an indispensable piece of gear. With the right WPB jacket, adventurers can confidently face the elements while staying dry, comfortable, and ready for whatever nature throws their way.

Layne | 09-03-2024 | Views 395 times

Sweatshirt Knit Fabric Series: Functions and Composition 1. Introduction to Sweatshirt Fabric Sweatshirt fabric is one of the most basic fabrics used in circular knitting. As the name suggests, it is used for making sweatshirts. In technical terms, it is know...

Layne | 09-02-2024 | Views 368 times

Are you looking for common swimwear fabrics? 1. Common Swimwear Fabrics In the blazing summer, it’s the season for swimwear to shine. So, what are the most commonly used fabrics for swimwear, and how should you select and care for them? 1.1 Lycra (DuPont L...

Layne | 09-01-2024 | Views 395 times

The Versatility of Polyester Stretch Fabric 1. Introduction Polyester stretch fabric is a standout in the textile industry, known for its flexibility, durability, and comfort. This fabric, made from a blend of polyester and elastane (or spandex), is widely us...

Layne | 08-31-2024 | Views 401 times

Nylon Stretch Fabric: The Perfect Blend of Strength and Flexibility 1. What is Nylon Stretch Fabric? Nylon stretch fabric is created by blending nylon fibers with elastane or spandex. Nylon itself is a synthetic fiber known for its toughness, resistance to we...

Layne | 08-22-2024 | Views 434 times

RPET Non-Woven Fabric: A Perfect Blend of Eco-Friendliness and Practicality 1. Background As environmental awareness increases, RPET non-woven fabric is becoming a popular choice in the market. RPET (Recycled Polyethylene Terephthalate) non-woven fabric not o...

Layne | 08-21-2024 | Views 507 times

Introduction to 10 Fabric Finishing Processes 1. Purpose of Fabric Finishing Finishing is a technical treatment that imparts color effects, shape effects (such as smoothness, velvety texture, stiffness, etc.), and practical effects (such as water resistance, ...

Contact us now for a free consult!